Celebrating Impact Label’s 60th Anniversary

Celebrating Impact Label’s 60th Anniversary

As Impact Label proudly celebrates its 60th anniversary, we are excited to introduce you to the driving forces behind our enduring success.

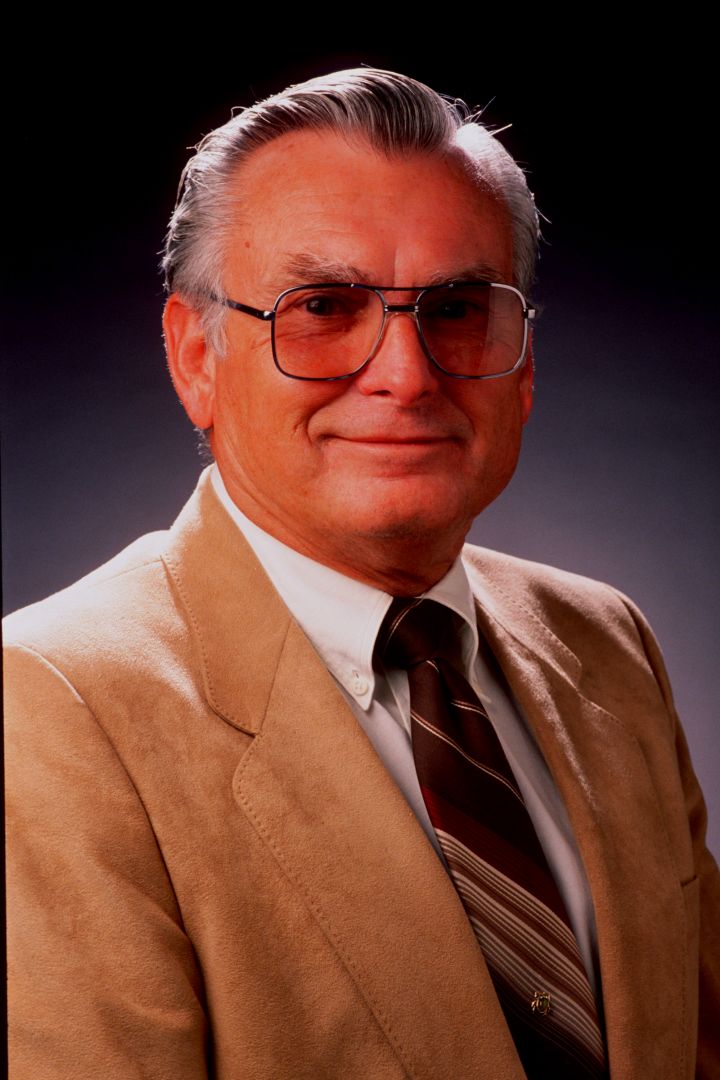

Ours is inherently a family company. Founded in 1964 by William Fogleson Sr., his daughter Susan Fogleson has been President for nearly twenty years. Her son, Matt Berry, serves as our Vice President, his innovative vision shaping our company’s trajectory.

Sara Cleveland, Office Manager, has worked for Impact Label wearing many hats since 1982. Abdullah Alyousif, MS and Director Of Engineering, spearheads technological advancements and keeps our operations on the cutting edge.

Our leaders sat down to talk about the rich history, achievements, and future aspirations of Impact Label.

The Beginning of Impact Label

Over the last 60 years, Impact Label has become one of the most successful label printing companies in the country. Throughout our history, we have strived to provide innovative and quality solutions while building meaningful, lasting relationships with our clients.

Susan Fogleson, President, recalled the dedication her father poured into the business. He worked long hours and weekends building the business. When he passed away unexpectedly in 2006, I was faced with making the decision of what to do with the company.”

Fogleson Sr. was deeply committed to building a company culture that values its employees. His daughter’s decision to carry on her father’s legacy was fueled by a desire to honor him and provide opportunities for the long-term, sometimes multi-generational, staff who had become like an extended family.

“I’m proud to work for a great family and I’d like to see it continue,” said Cleveland. “I met my husband here, my kids have worked here. It’s always been a family-oriented situation.”

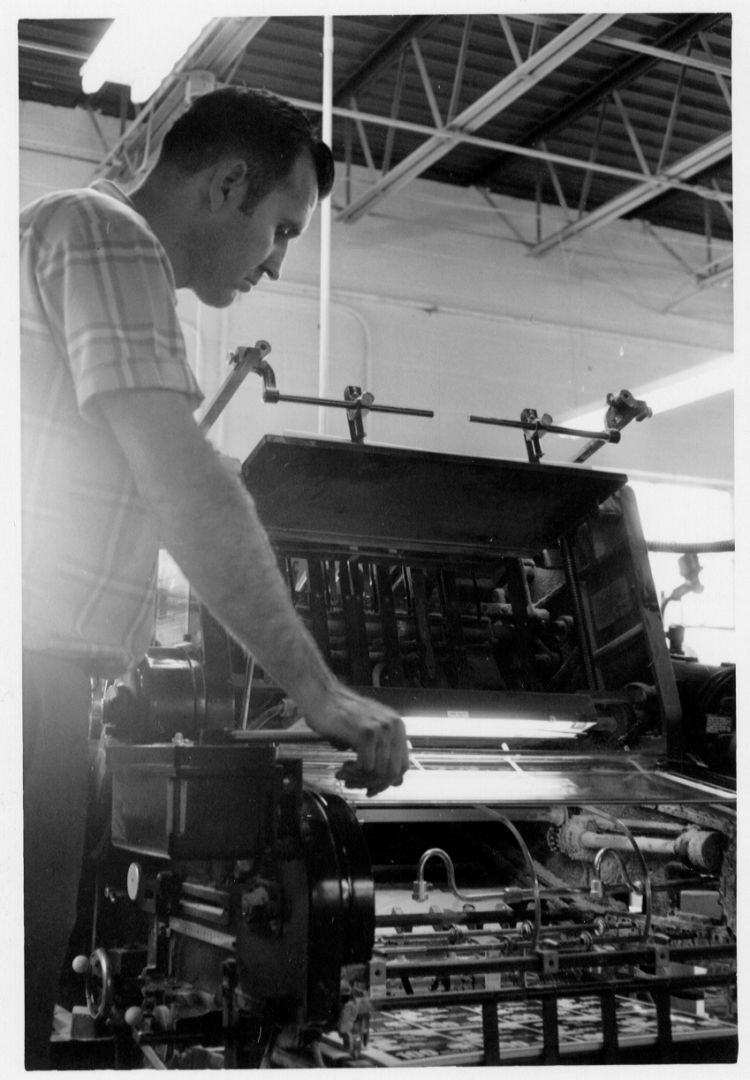

Berry grew up working at the company during summers. Once Fogleson Sr. passed away, he decided to join the business in a full-time capacity. His involvement in various roles within the company, from working on the shop floor to overseeing the entire business, equipped him with invaluable insights into the intricacies of label production and customer needs.

From Analogue to Digital: The Challenges of New Technology

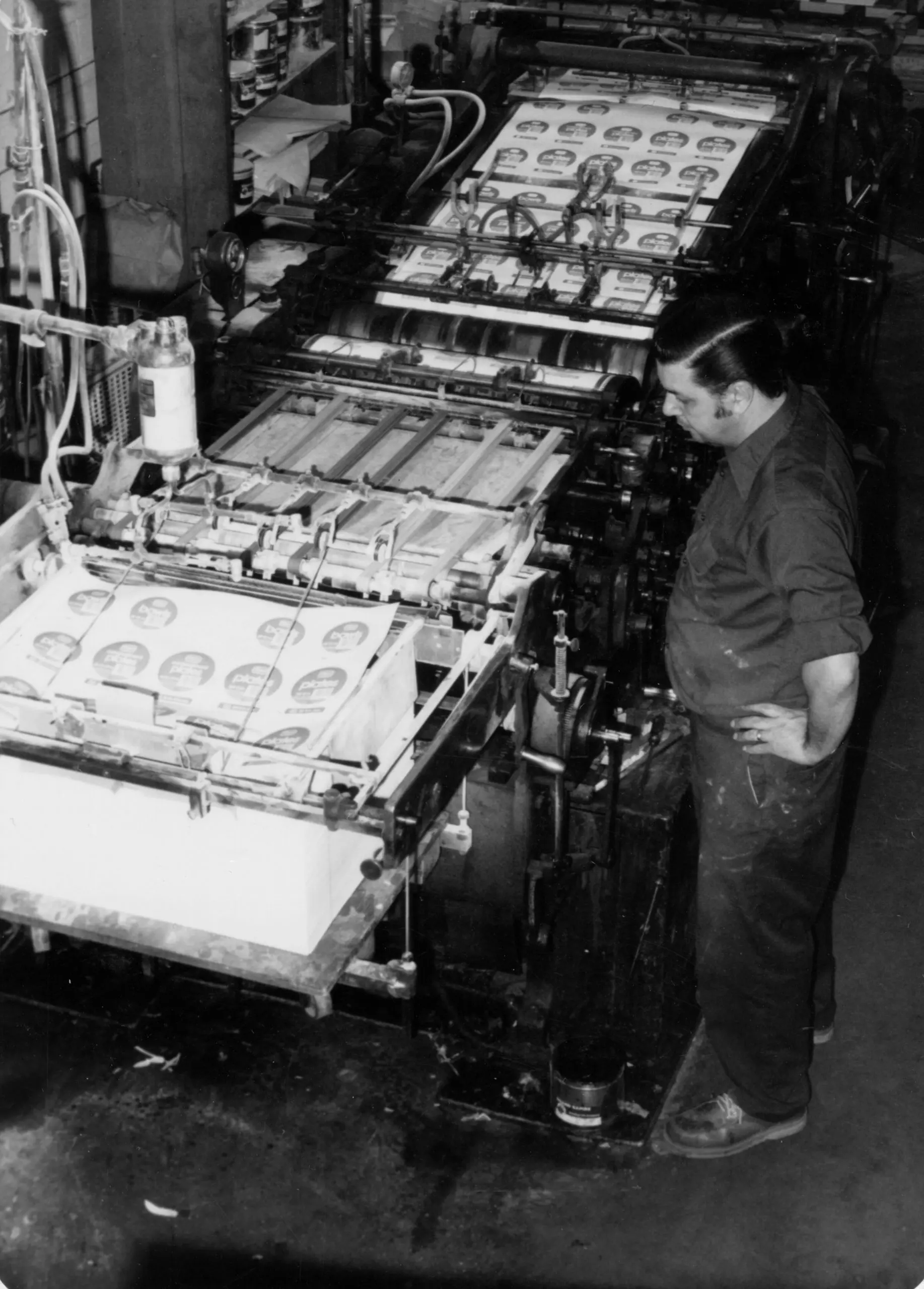

Cleveland recalled the manual processes of the past, where tasks such as order entry and documentation relied heavily on manual labor and meticulous attention to detail. As technology progressed, Impact Label had to pivot to digital solutions to streamline operations and enhance efficiency. This enabled them to shorten their lead times drastically, from a timeline of 4 weeks to just 5 days–that’s from order receipt to shipping.

“It’s the Amazon effect,” Cleveland continued. “Now you can order something and have it tomorrow. Those changes are what made us realize the urgency, and that people aren’t going to wait for a twenty-one-day lead time.”

Alyousif believed that one of the best decisions the company made was investing in new technology, including high-speed UV printing and digital converting systems.

“In time, we’ve gone from analog to digital and looking to invest in the best possible solutions in printing technology,” Alyousif said. “We make sure we’re always producing the quality and branding colors that the customers are expecting.”

This shift towards automation and digitalization has significantly increased production speeds, delivering quicker turnaround times and higher-quality outputs for clients.

“We still have some core older technology but in the last four years we’ve moved to digital and automated processes that require less labor and more skilled technicians,” Berry explained. “Machines do the work and provide the highest quality products. We’re here to support the machines and make sure they stay running.”

These advancements have not only enhanced Impact Label’s efficiency and competitiveness but also reaffirmed our commitment to delivering top-quality products to our longstanding customer base. The transition wasn’t easy, and there were certainly roadblocks along the way.

“It was tough for my father and the previous generation because purchasing new technology was a risk,” Fogleson explained. “Investing in the newest and greatest was a challenge.”

Cleveland reflected on the challenges of managing multiple locations in an era before digital communication, where cumbersome processes and costly shipping methods hindered productivity.

“We had four locations and all communication was through the mail, fax, or phone,” Cleveland continued. “We’d process everything here and ship out jobs to the other three facilities through UPS. It took a lot of time, and it was costly.”

In the 60s and 70s, business was driven by a physical presence and sales teams across different states. However, when Fogleson took over the company, leadership realized that maintaining multiple locations was no longer viable, prompting a gradual consolidation process.

In 2014, faced with maxed-out capacity and antiquated equipment at their original office, Impact Label made the bold decision to build a new facility. Berry was deeply involved in the planning and execution of the new building. Berry recounted the challenges during consolidation, particularly in integrating new technologies and upskilling employees.

“We had difficulty managing employees and inventory across different locations. We had to bring a new technology that we weren’t familiar with into the building,” Berry said. “We were learning about lean manufacturing and moving away from antiquated processes and procedures. We started to figure out a better way to do things.”

Through meticulous planning and collaboration with local partners like AVB, Impact Label successfully navigated these hurdles and emerged stronger than ever. The modular design of the new facility, with provisions for future expansion, reflects a forward-thinking approach and positions us for future growth and scalability.

“I helped with laying out the machinery and using the space in a way that allowed us to grow,” Berry said. “The back wall is removable, so we could expand if we needed to double the size. The goal was to set us up for the future.”

Aside from technological advancements, Impact Label has adapted our sales and marketing tactics to be digital.

“Another huge shift for us was going with KARMA jack and eliminating sales reps,” said Berry. “We never would have thought of doing our marketing through digital technology. It was always face-to-face, having meetings in person–but that’s not the way business is done today. How we’re going to grow the business moving forward is completely different than the last 58 years.”

Reflecting on Legacy & The Future of Impact Label

Success for Impact Label has been defined by longevity, community impact, and our people. We have always prioritized building great, long-term relationships with both our customers and employees.

To other business owners and leaders, Fogleson emphasized the importance of embracing change and seizing opportunities for growth.

“Don’t be afraid of the future,” she advises. “If you don’t jump in and embrace it, you’re going to be left behind.”

Alyousif added, “Having the right leadership, support, and people makes all the difference.”

Fogleson shared that she’s proud to have been able to continue her father’s legacy. Looking ahead, the team expressed a sense of excitement and optimism for the future, with a commitment to continued growth, innovation, and community engagement.

“There are not many businesses that last 60 years, it’s a great milestone for everyone,” said Berry. “I see us continuing to stay at the forefront of our industry and be a part of the community. Hopefully, we’ll see Impact go to 100 years.”

To celebrate a remarkable 60 years, Impact Label is hosting an Open House on September 19th. We invite our clients, partners, and friends to join us in commemorating this achievement with us!

Guests can look forward to a fully catered event, exclusive tours of our facility, demonstrations of our machines in action, and opportunities to meet our team, socialize, and network. RSVP here. We can’t wait to see you there!