RFID vs. QR Codes: Which Is Better for Your Business Inventory Management?

RFID vs. QR Codes: Which Is Better for Your Business Inventory Management?

Keeping track of inventory is one of the biggest challenges businesses face. Missing items, incorrect counts, and slow tracking methods can lead to costly mistakes and lost revenue. Whether you’re running a warehouse, retail store, or manufacturing facility, having the right technology in place can make all the difference.

Two of the most popular tools for inventory management are RFID (Radio Frequency Identification) and QR codes—but which one is better for your business? Let’s break down how they work, what sets them apart, and how to decide which is the best fit for your operations.

What Are RFID and QR Codes?

RFID (Radio Frequency Identification)

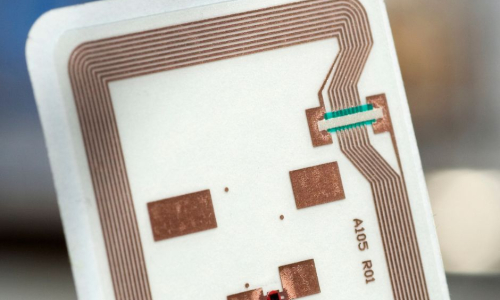

RFID uses radio waves to communicate between a tag (attached to a product or asset) and a reader that collects data wirelessly. RFID tags can be either passive (powered by the reader’s signal) or active (powered by a built-in battery). Unlike barcode or QR code scanning, RFID does not require direct line-of-sight to be read, making it highly efficient in fast-moving operations.

How RFID Works in Inventory Management:

- Items are tagged with RFID labels embedded with a unique identifier.

- An RFID reader scans multiple items at once, even through packaging or from a distance.

- The data is transmitted to an inventory management system in real-time.

QR Codes (Quick Response Codes)

QR codes are two-dimensional barcodes that store information such as serial numbers, URLs, or product details. They require a scanning device (like a smartphone or barcode reader) to be interpreted.

How QR Codes Work in Inventory Management:

- Each item is labeled with a printed QR code containing product or tracking details.

- A scanner or smartphone reads the QR code to update inventory records.

- Information is stored and accessible in the inventory system.

Comparing RFID and QR Codes for Inventory Management

- Scanning Efficiency and Speed

- RFID: Can scan multiple items at once without needing direct line-of-sight. This is a game-changer for businesses with large-scale inventory (warehouses, retail, logistics).

- QR Codes: Require manual scanning of each individual item, which can slow down operations in high-volume environments.

- Accuracy and Reliability

- RFID: Minimizes human error since the scanning process is automated and requires no manual input.

- QR Codes: Depend on proper label placement and clear visibility to be read correctly. Smudges, damage, or low-quality prints can cause scanning issues.

- Cost and Implementation

- RFID: Requires higher upfront investment for readers, software, and tags, making it more expensive to implement—especially for small businesses.

- QR Codes: Are low-cost, since they only require a printed label and a standard barcode scanner or smartphone.

- Durability and Lifespan

- RFID: Tags can be embedded in products and are often weatherproof, heat-resistant, and tamper-proof, making them ideal for long-term asset tracking.

- QR Codes: Are printed on labels or packaging, which can be torn, faded, or damaged over time.

- Scalability and Automation

- RFID: Highly scalable for businesses handling thousands or millions of items, allowing automation and real-time tracking.

- QR Codes: More manual and time-consuming for large inventories but work well for small businesses with limited inventory tracking needs.

- Security and Data Storage

- RFID: Can store more data per tag and can even be encrypted for better security.

- QR Codes: Store limited information and can be easily copied or altered.

Which One is Right for Your Business?

Choose RFID if:

✔️ You manage a large-scale inventory (warehousing, logistics, healthcare, retail).

✔️ You need real-time tracking and automation.

✔️ You require durable, long-lasting labels that don’t rely on visibility to scan.

Choose QR Codes if:

✔️ You have a small to mid-sized inventory with limited tracking needs.

✔️ You need a low-cost solution that is easy to implement.

✔️ You want to use smartphone-based scanning for customer engagement or product verification.

Optimize Your Inventory Management with Impact Label

Choosing the right inventory management solution is critical for efficiency, accuracy, and the overall success of your business. At Impact Label, we specialize in high-quality labeling solutions that support seamless operations across industries. Whether you need durable labels, advanced tracking technology, or customized solutions to fit your unique needs, we’re here to help. Let’s create a labeling strategy that works for your business—contact us today!