What Impacts The Cost of Custom Product Labels?

The price of printing custom product labels will vary widely across the custom label printing industry. Different label options can have a significant impact on pricing. The cheapest product label is not necessarily the most efficient or cost-effective. The best way to make sure you’re getting the best value for your custom product labels is to understand what elements impact pricing and which are most important to you.

Materials

Like any other manufactured item, your product label’s material will drive its cost. Certain materials simply cost more than others due to market forces, how much your label supplier has in stock, their relationship with material providers, etc. When designing your product label you should choose a material that is high-quality and appropriate to your product to avoid unsightly rips, peeling, fading, and crumbling. Cost should be secondary to quality and durability. Communicate to your custom label printer how long you need your product label to last, what purpose it will serve, what environmental elements it may be exposed to, and other details that will contribute to the design.

Adhesive

Another material that feeds into the cost equation is your choice of adhesive. Each type of adhesive has different performance characteristics and costs. For example, some adhesives work better on wood, while others are better suited for glass. Your custom label printer will walk you through the options best for your product label.

Colors

The type of ink and how many colors your product label requires will impact the price. Why? More colors mean more steps for your label printer, more ink use, and longer setup and printing time, all of which lead to higher expenses. Certain types of ink, such as fluorescent and metallic inks, also tend to be more expensive than standard colors. While cost is important, so is the performance of your product label. Choose high-quality ink that won’t smudge or fade.

Shipping

How you prefer your product labels to be packaged and shipped will also affect the cost. Buying in bulk may save you money when ordering your product labels.

How To Save On Product Label Costs

The best way to save on product label costs is to communicate with your custom label printer. Be transparent about your goals, and be open to listening to their suggestions. It’s also important to continuously test your product labels. This guarantees that your decisions are leading to the best possible customer experience as people interact with your product labels.

Leave A Lasting Impact

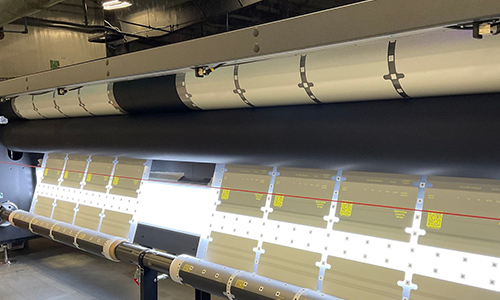

With top-of-the-line printing equipment and years of expertise, Impact Label is the best in custom label printing. We provide tailored design solutions for any industry. Learn how we can help your business make a lasting impact.