Flexographic Printing vs. Other Printing Methods: Which is Right For Your Business?

When it comes to printing custom labels, businesses have several options to choose from, each with their own unique advantages and disadvantages. In this blog, we’ll explore flexographic printing and compare it to other printing methods to help you determine which is right for your business.

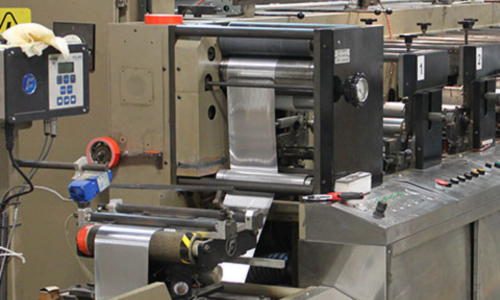

Flexographic Printing

Flexographic printing is a type of relief printing that uses flexible plates made of rubber or photopolymer. The plates are wrapped around a cylinder, which is then inked and used to transfer the image onto the substrate. Here are some of the advantages of choosing flexographic printing:

1. Speed

Flexographic printing is often used for high-volume printing jobs, such as labels, packaging, and newspapers because of its fast production speed.

2. Versatility

Flexo can print on a wide variety of materials, including paper, plastic, film, and metal. Flexographic printing can be used to print a range of colors, from basic spot colors to full-color images.

3. Quality

This type of printing produces high-quality images with crisp lines and sharp details. This is because the flexible plates used in this process can conform to the contours of the substrate, resulting in a more precise print.

4. Cost-effective

The cost per print is relatively low, making it an attractive option for businesses with high-volume printing needs.

Other Printing Methods

There are several other printing methods available that may be better suited for certain types of businesses.

Digital printing has become increasingly popular due to its ability to produce high-quality images with variable data. This makes it ideal for businesses that need to print personalized items, such as direct mail or promotional products. Digital printing also has a lower setup cost compared to flexographic printing, making it a better option for businesses that need to print smaller quantities.

Offset printing is another printing method for businesses that need to print high-quality images with a wide range of colors. This method uses plates made of metal or plastic, which are etched with the image to be printed. The plates are then used to transfer the ink onto a rubber blanket, which in turn transfers the image onto the substrate. This process allows for precise color matching and the ability to print complex images with gradients and halftones.

Ultimately, which printing method you choose for your business will depend on a variety of factors, including the type of product being printed, the quantity needed, and the desired quality of the final product. Carefully consider each option and work with a trusted printing partner to make an informed decision for your labeling project.

Custom Label Printing at Impact Label

We lend our expertise and help you navigate the challenges and specifications of labeling for your field. Contact us to create a customized label printing solution for your business.