Things to Consider When Ordering Custom Labels from Impact Label

There are a number of things to consider when ordering custom labels and the team at Impact Label is here to help. With over fifty years in business, we have worked with clients in a wide range of industries to choose the best custom label for their needs. In this post, we will look at some of the options available when printing your custom labels.

Shape. While the most economical choice is using standard shapes, there are times when a custom label shape is necessary. If your product requires a custom shape, Impact Label offers die-cutting where we can cut labels in nearly any shape you desire.

Color. There’s no question that deciding on colors is an important part of the custom label making process. Impact Label uses a host of inks that include standard CMYK or Pantone spot colors, as well as custom metallics and high visibility colors.

Substrate. When choosing a substrate, it’s necessary to consider how the labels will be used. At Impact Label, we have a number of substrate options, including vinyl, polyester, polycarbonate, metallic, or reflective.

Finishing. There are some custom labels that requiring a finishing treatment. These finishing treatments can include die-cutting, embossing and debossing, domed capping, spot gloss or UV coating, and lamination. To learn more about our finishing options, click here.

Adhesive. The best adhesive for your label depends on its intended use. Impact Label will work with you to select the most appropriate adhesive for your label’s application to ensure it stays in place and can withstand the elements for the lifetime of your product.

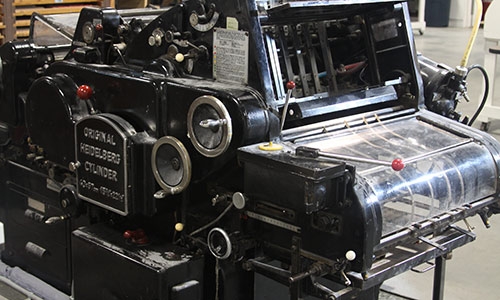

Printing Process. The best printing process for your custom label will depend on a number of factors, including intended use and quantity. At Impact Label, we have the knowledge and equipment necessary to determine what printing process is best for your custom labels.